What is Industry 5.0?

A NEW CONTEXT

Industry 5.0 represents the next evolutionary phase in the manufacturing process, where human intelligence e creativity are integrated with advanced technologies such as articficial intelligence (AI) robotics, Internet of Things (IoT), and new sustainability solution devices. Unlike Industry 4.0, which emphasizes automation and connectivity, Industry 5.0 focuses on creating a more human-centered, sustainable, and resilient industrial ecosystem.

INDUSTRY 5.0 AND METROLOGY

Industry 5.0 brings a significant transformation in the metrology by enhancing precision e efficiency through collaboration between human expertise and new measurement device systems. The introduction of advanced sensors, real-time data analysis, and AI algorithms enables smarter, adaptive, and more accurate measurement process. This shift allow for enhanced customization, better decision-making, and the ability to handle complex measurement challeges in different industries such as automotive, aerospace, marine equipment, and consumer products.

INDUSTRY 5.0 AND METROLOGY GATE

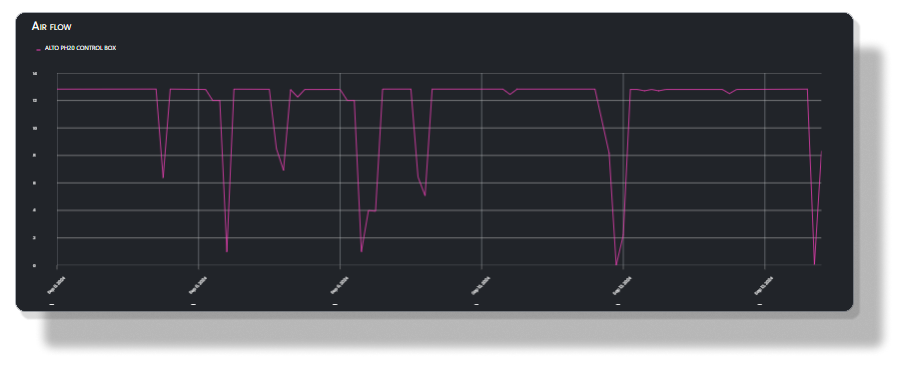

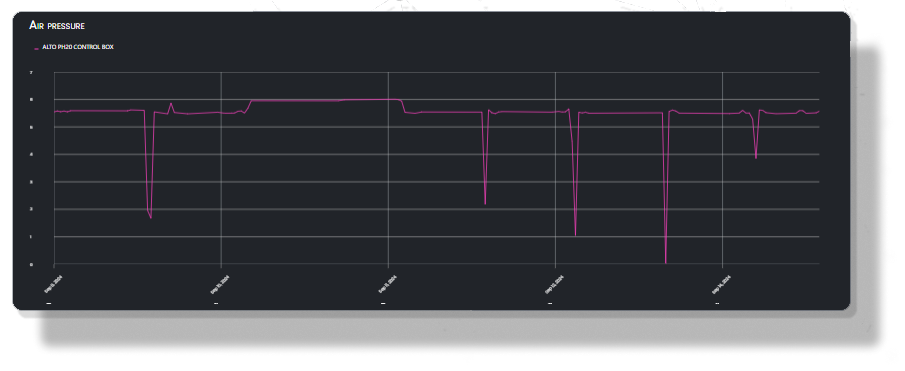

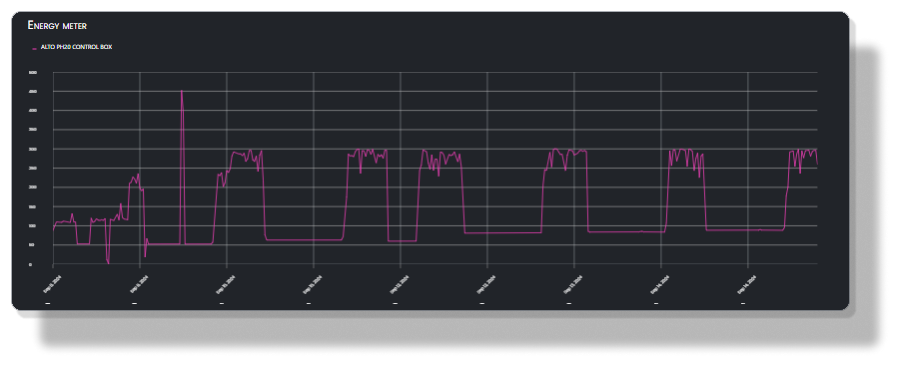

The search for innovation and smart solutions is an ongoing target of Metrology Gate, and to address the 5.0 transition challenge we provide new solutions that allow to monitor the energy performance of measuring instruments.

CMMs require significant energy, particularly in large-scale manufacturing environments, and the use of device that can control the environmental impact of the measuring instrument is crucial for the 5.0 Metrology.