What is a metrological laboratory?

Metrological laboratories are the rooms where the measuring instruments (CMMs, portable arms, roughness meters, 3D laser scanners, etc.) are located and used.

Metrology laboratories address the requirement of manufacturers and customers to measure parts with extreme precision, where the need for micron accuracy is critical.

What are the environmental conditions that a metrological laboratory shall meet?

To meet increasing accuracy requirements, the Metrology rooms shall comply with environmental standards specified by the manufacturer of the metrology equipment. The task of maintaining a proper environment typically falls onto the personnel in the metrology lab. These individuals must ensure the air conditioning/heating (HVAC) is optimal.

The ISO 1, ISO 17025 and ASME Y14.5 standards state that 20 º C (68 º F) is the reference temperature for the geometric specifications of the parts.

Therefore, the HVAC system must work to constantly provide a temperature of 20 degrees; any fluctuation of this ambient temperature is tolerated only within certain limits and shall be logged. It is crucial that inside the metrology lab the temperature never undergoes significant fluctuations, which can be a major component of the inaccuracies related to the measurements.

While the temperature may be the most critical environmental element, it is not the only environmental element that should be monitored and/or taken into account within a metrological laboratory. Other environmental parameters that may affect the measurement of parts include:

- Humidity: the humidity in the metrological room may affect the geometrical characteristics of the measured parts, with high humidity, for example, metals like gauge blocks or machine parts resting in the room will rust quickly. For this reason, the humidity shall be constantly controlled.

- Vibration: this is a concern especially on the measurements utilizing constant contact scanning tools, which is a very precise process. Very small oscillations affect the quality and accuracy of the measurements. As CMMs continue getting more accurate, this environmental factor becomes more significant to meet higher standards.

- Brightness: with the introduction of video inspections, even illumination becomes a factor to be considered. Ambient light is an important variable when using the video probe system such as laser scanner or video probes. For accurate and repeatable inspection, the ambient environment lighting should be as consistent as possible and any changes in ambient lighting can potentially affect the system’s performance.

While humidity, vibration, and brightness level can directly affect the measured parts, there is an extra environmental parameter that indirectly affects the operations: the air quality.

As we all know, human well-being is based on oxygen and CO2 is basically what can be called “used air”; too much carbon dioxide leads to tiredness and lack of concentration and can cause headaches in sensitive people.

According to DIN 1946, to have a healthy environment in a workplace, the maximum value of CO2 shall be below 1500 ppm with a recommendation of 1000ppm. To help put these values in perspective, fresh air is significantly lower with a value between 350-500 ppm. As Metrology labs are closed environments it is becoming more important to monitor the CO2 levels and ensure that metrology personnel are working in a healthy environment.

Metrological laboratories and IoT: metrology 4.0.

As we saw, the monitoring and maintenance of all the environmental parameters are necessary to obtain the most constant and accurate results possible.

For these reasons, the metrological laboratory should be geared with IoT technology devices. These instruments allow the continuous monitoring of the temperature level and the different environmental parameters, including humidity, air quality, vibration, and CO2 levels.

These devices allow us to transform the metrology room into a real 4.0 environment.

Metrology Gate and the environmental parameters of the metrology laboratory

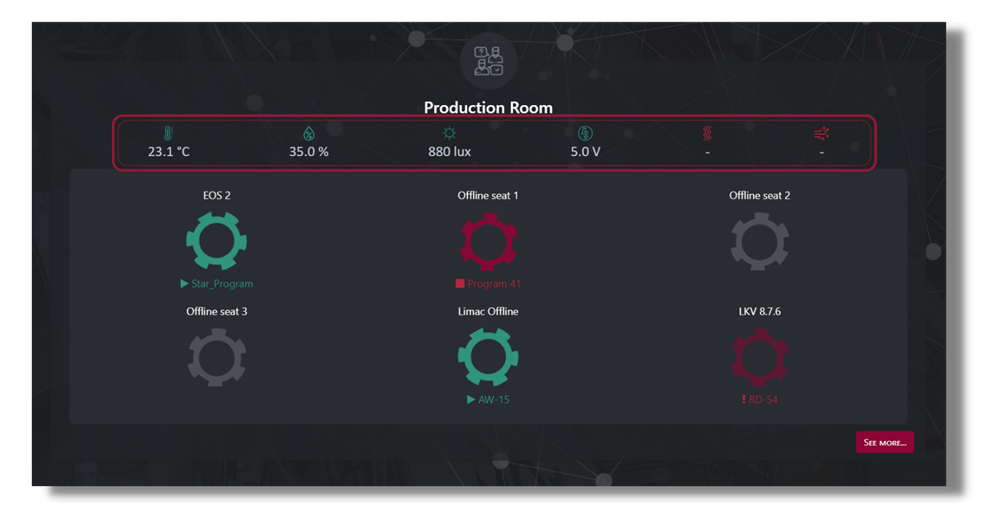

Metrology Gate fits fully into the context of Industry 4.0. and with the release of version 2.6, the environmental parameters of your metrology room can be tracked. Through a dedicated client, Metrology Gate can communicate with the IoT devices of the metrological laboratory and send the data in real-time directly in the web application, where you can see them in the dashboard of the laboratories.

A click on the indicators will open the detail page, where graphs show the trend of all environmental parameters, with selectable time intervals.

Metrology Gate Environmental Parameter Reports

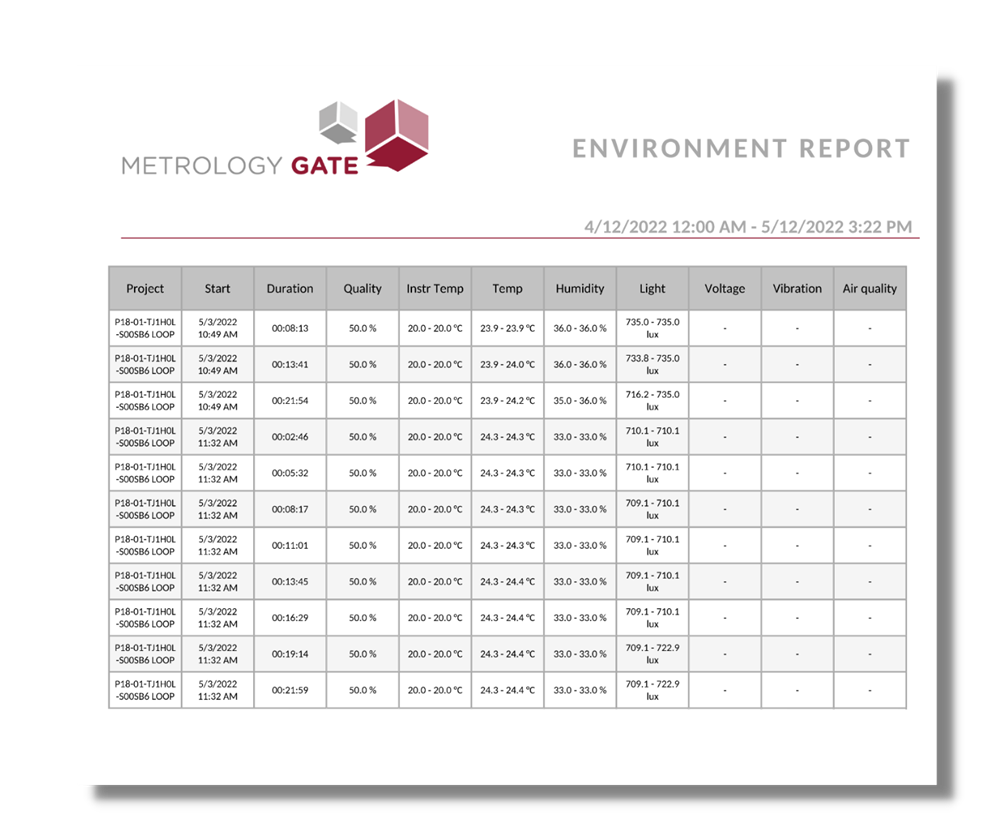

Additionally, Metrology Gate offers the possibility to download reports in PDF format. There are two possible reports:

- All the environmental parameters in a certain period of time: with this report the trends can be observed as well as the historical charts of the temperature, humidity, brightness, and all the environmental parameters.

- Traceability: with this PDF report, besides the history of the environmental parameters, you get the list of the measured parts during the requested period. This is proof that the inspection room was maintained within the standards during the entire period when the inspection was done and the parts were resting in the room.

With these two reports, it is possible to visualize all the activities carried out in that particular room, which instrument was used, which measurement was performed, and all the environmental information collected during the operations.

With a high level of details, for each measured part, the report will provide information on:

- the runtime of measurements

- percentage of out of tolerances (OOT)

- the temperature of the instrument during each inspection

- all the environmental parameters in the period

- which instrument performed the inspection

This is a real summary of the quality that can be sent automatically by Metrology Gate thanks to the auto alert system.

The traceability reports prove the environmental conditions of the metrology room during the operations were in the optimal conditions when the measurement was performed, leaving to the metrologist the task of dealing only with the inspections with no worries about recording the environmental data.

A jump into a real 4.0. environment

As we have seen, the control and maintenance of high environmental standards play a fundamental role in the daily operations of the metrological room.

In addition, these measures allow for improving the general well-being of the metrology staff working in the laboratories.

This is why you should take the right tools, and Metrology Gate and IoT technology support you in creating a real 4.0 environment!

Want to discover more and make a jump into 4.0. Metrology? See other Metrology Gate features or contact us!