As industries continue to evolve, Industry 5.0 has emerged as a crucial step forward. While Industry 4.0 focuses on automation, data exchange, and smart systems, Industry 5.0 is aiming on a human-centric approach, placing greater importance on sustainability, and enhanced collaboration between humans and machines.

This transformation also extends to metrology, where precision measurement is critical in ensuring quality and efficiency in manufacturing.

Sustainability is the key element of this transition, presenting challenges and opportunities for metrology. Measurement sysyems like CMMs often require significant energy, particularly in large-scale manufacturing environments.

While industries strive to reduce their carbon footprint, the companies’ awarness of their environmental impact within the market and their actions to mitigate will be fundamental to facing this new context.

So metrology needs to adopt energy-efficient technologies, such as smarter data processing and devices that help operators monitor the energy consumption of the measuring instruments.

Additionally, by enabling more environment-responsable measurements, metrology operators can help reduce wast, minimize rework, and optimize resource use.

The search for innovations and smart solutions is an ongoing target of Metrology Gate, and to address the 5.0 transition challange we are putting into practice the Environment Gate system, a tool that allow us to monitor energy performance of measuring instruments connected to our software.

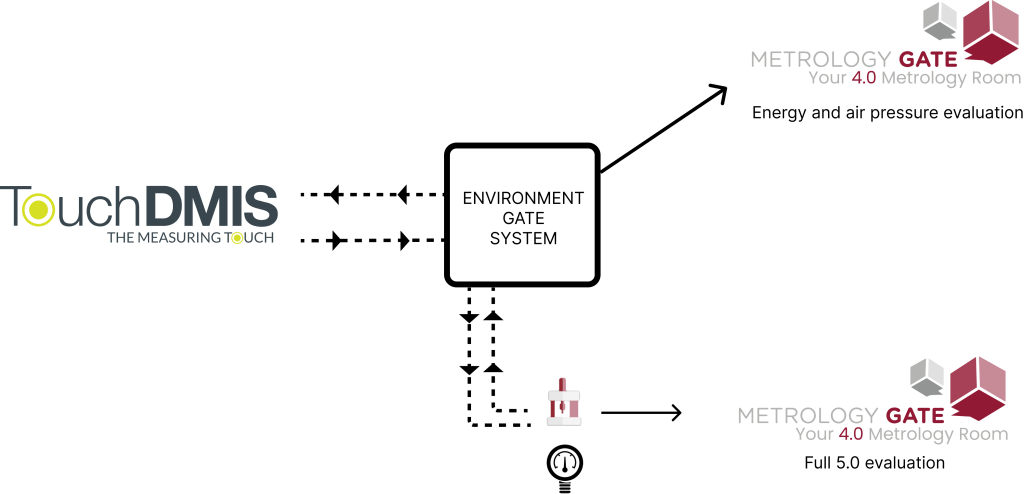

Thanks to an integration with TouchDMIS measuring software, the Environment Gate system allow to reading data from the CMM and provides active real-time energy-consumption information.

How does Environment Gate system work?

The Environment Gate system works in two ways: the hardware mode (through TouchDMIS and CMM) and the 5.0 evaluation mode (Metrology Gate).

Firstly, this tool is connected with the CMM and the measuring software. When TouchDMIS is not used and goes into energy-saving mode, Environment Gate switches off the air, and delivers it back when operators resume to work, increasing energy saving.

In 5.0 evaluation mode, all activity information about CMM is collected into Metrology Gate. These data, available through the Metrology Gate dashboards, allow operators to understand the current state of their instrument’s energy consumption. The detailed insight makes it possible to identify patterns in usage and areas where energy-saving measures could be further implemented.

What kind of information Metrology Gate can retrieve from the CMMs?

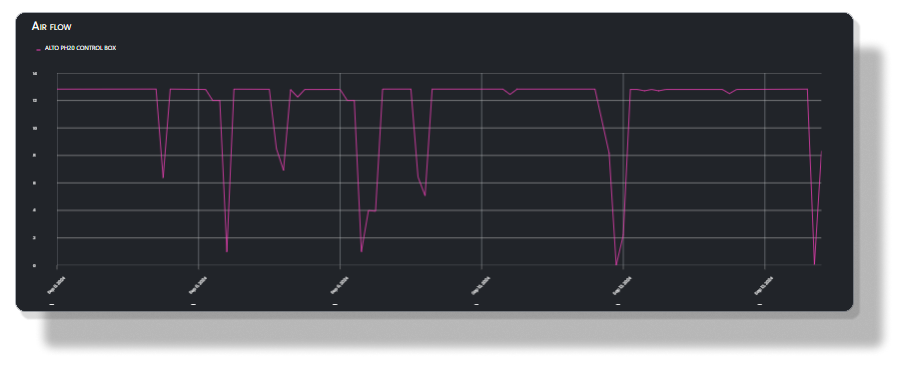

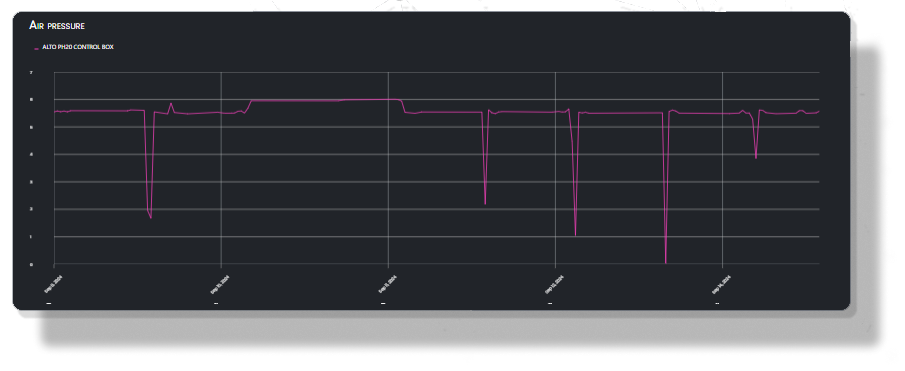

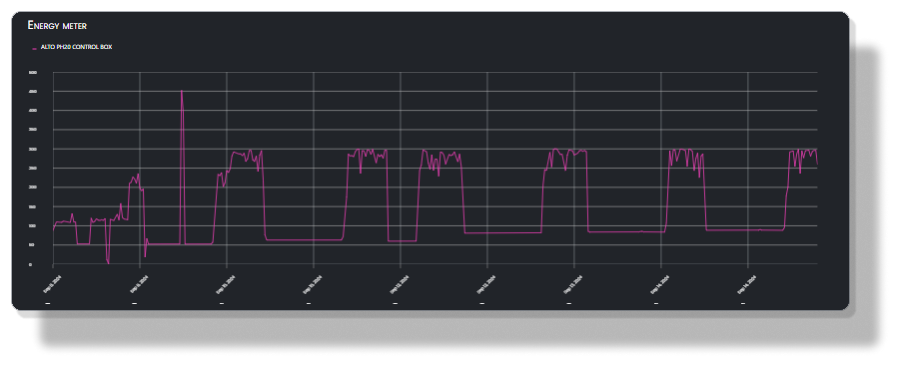

From the web-application, operators can see real-time charts of:

- Air-flow: allows us to accurately calculate the costs of using the CMMs, considering how much air is consumend knowing that TouchDMIS energy-saving mode allows us to optimize air use

- Air pressure: allows us to monitor air pressure fluctuations, providing us with valuable information whether the CMM air devices are in good status

- Energy consumption of the CMMs: another important index to establish the costs of measuring instruments because it precisely detects all consumption of the device connected to the CMM (PCs, controllers, sensors, etc.)

Environment Gate system is an open-platform controlled by a microprocessor that can handle a range of sensors (digital-analog sensors, and Modbus protocol), such as temperature and humidity monitors that are required by ISO/IEC 17025-compliant companies. Thereby, Metrology Gate will be able to compare laboratory temperatures with the CMM’s temperature during inspections, providing evidence that measurements were made in a controlled environment.

Furthermore, Environment Gate system is a stand-alone device installed upstream of the CMM and which will distribute power to the CMMs. So, it is compatible with all CMMs regardless of the measurement software. In the case of TouchDMIS, it manages the energy-saving mode with an automatic switch off – switch on function.

The road to 5.0 transition

The shift towards Industry 5.0 presents a unique opportunity fot the metrology industry to embrace technological advancements while also contributing to sustainability goals. By adopting a system like Environment Gate, we can play an active role in driving the industry toward a more sustainable and efficient manufacturing context.

Want to be part of 5.0 transition? Contact us and we will discuss further.