![]() The manufacturing landscape is experiencing a significant transformation due to the emergence of Industry 4.0 and the shift toward smart factories.

The manufacturing landscape is experiencing a significant transformation due to the emergence of Industry 4.0 and the shift toward smart factories.

Central to this revolution is the need for precise, reliable, and real-time dimensional measurement, which has traditionally been delivered by Coordinate Measuring Machines (CMMs).

Although these machines have long been the foundation of quality control, the evolving demands of modern production environments are changing their roles and integration.

From traditional CMMs to the Smart Metrology

CMMs have historically operated in isolated quality control labs (as we like to call them: Metrology Rooms), delivering accurate inspections for finished parts. However, the smart factory demands more. Interconnected machines, cyber-physical systems, and real-time feedback loops characterize today’s production systems. In this context, CMMs must evolve from standalone inspection tools into active nodes within a digital ecosystem.

Modern CMMs are now being designed to interact with Manufacturing Execution Systems (MES), Enterprise Resource Planning systems (ERP), and other digital platforms. The goal is to create a closed-loop process where data flows seamlessly from measurement to decision-making.

Emerging trends in CMM technology

Several trends are pushing CMMs toward greater adaptability and intelligence:

- Automation and robotic integration: Automated part loading and collaborative robot arms reduce manual handling and improve throughput

- Multi-sensor capabilities: The integration of tactile, optical, and laser sensors enables a broader range of measurement strategies.

- Real-time data analytics: Advanced software platforms now offer Statistical Process Control (SPC) in real-time, enhancing quality and reducing scraps.

- Remote monitoring and maintenance: Remote diagnostics and predictive maintanance tools minimize downtime and support continuous operation.

Metrology Gate: the digital backbone of smart measurement

A key enabler of this transformation is Metrology Gate, the 4.0 metrology platform designed to bring transparency, traceability, and control to measurement systems.

Developed to meet the challenges of modern manufacturing, Metrology Gate acts like a centralized hub for CMM monitoring, analytics, and remote management.

Let’s take a look of some of the key features of Metrology Gate that enables the Smart Factory:

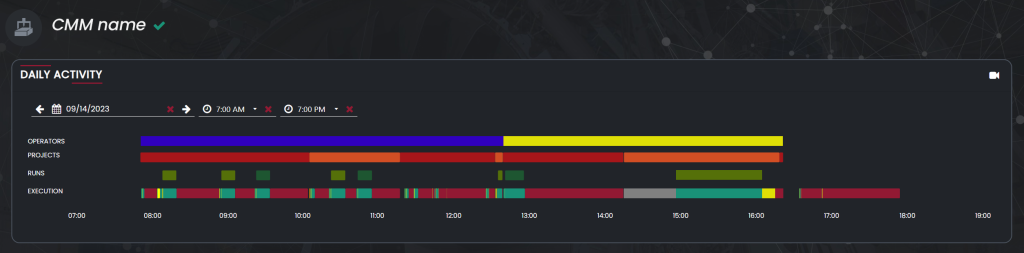

- Advanced and remote machine monitoring: Metrology Gate allows operators to monitor the status of all connected CMMs in real-time. Whether on the shop floor or metrology room, quality operators can monitor machine daily activities, program execution, and downtime statistics with full dashboards.

- Centralized data collection: All inspection results and CMM activities are automatically collected and stored online and can be recovered in any moment by any device.

- SPC and analytics: Metrology Gate supports SPC by analyzing inspection data in real-time to detect trends, deviations, and process instability (CP/CPK). This allows manufacturers to take proactive quality decisions and implement corrective actions before next defects occur.

- Alerts and predictive maintenance: With configurable alert systems, operators receive notifications about potential errors, overdue calibrations, or any other CMM maintenance issues. This feature helps reduce unplanned downtime, guarantees CMM performance and extend machine lifetime.

- Seamless integration: Metrology Gate is designed to integrate easily with existing CMM software (like TouchDMIS), offering a plug-and-play solution that enhances digital metrology workflows without major disruption

Integrating CMMs into the Smart Factory ecosystem

The integration of CMMs into smart factories goes beyond merely updgrading hardware; it involves establishing a network of intelligent, communicative systems. Platform like Metrology Gate offer the digital infrastructure necessary to link these systems, turning measurement data into actionable intelligence.

By bridging the gap between inspections and production, Metrology Gate empowers manufactures to:

- React to quality deviations in real-time.

- Visualize CMMs and inspections data across different plants.

- Reduce waste and rework through faster feedback.

- Maintain continuous compliance with quality standards.

As the smart factory continues to evolve, the role fo metrology is expanding from passive measurement to active process control. CMMs, supported by smart solutions like Metrology Gate, are becoming indispensable components of the digital manufacturing chain.

By enabling real-time data access, predictive insights, and global connectivity, Metrology Gate is not only modernizing how we measure but also how we manage and improve quality at scale.

Want to be part of 5.0 transition? Contact us and we will discuss further.